Blending, Mixing & Dosing

Whether you are mixing and dosing fruit into a yoghurt base, hydrating powder for a pre-mixed beverage, or anything in between, our team is here to help.

Systems range from batch processes through to large scale inline proceses – we will design the system to suit your reqirements.

Thermaflo Blending, Mixing & Dosing Equipment

Thermaflo Fruit Mixing & Dosing Skids

Capacity: From Up to 2000L/hr to Up to 6000L/hr

Instrumentation and Control Panel:

- Yoghurt and Fruit Line Flow Meters

- VSD on pumps

- Level transmitter on balance tank

- Full PLC and HMI

- CIP program dedicated to the mixer

- Water flush program

- VSD controlled dynamic mixer motor

Construction: Skid and framework made with stainless steel 304, pipework, chambers and balance tank made with 316 stainless steel

Pumps: Stainless steel 316 sanitary pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

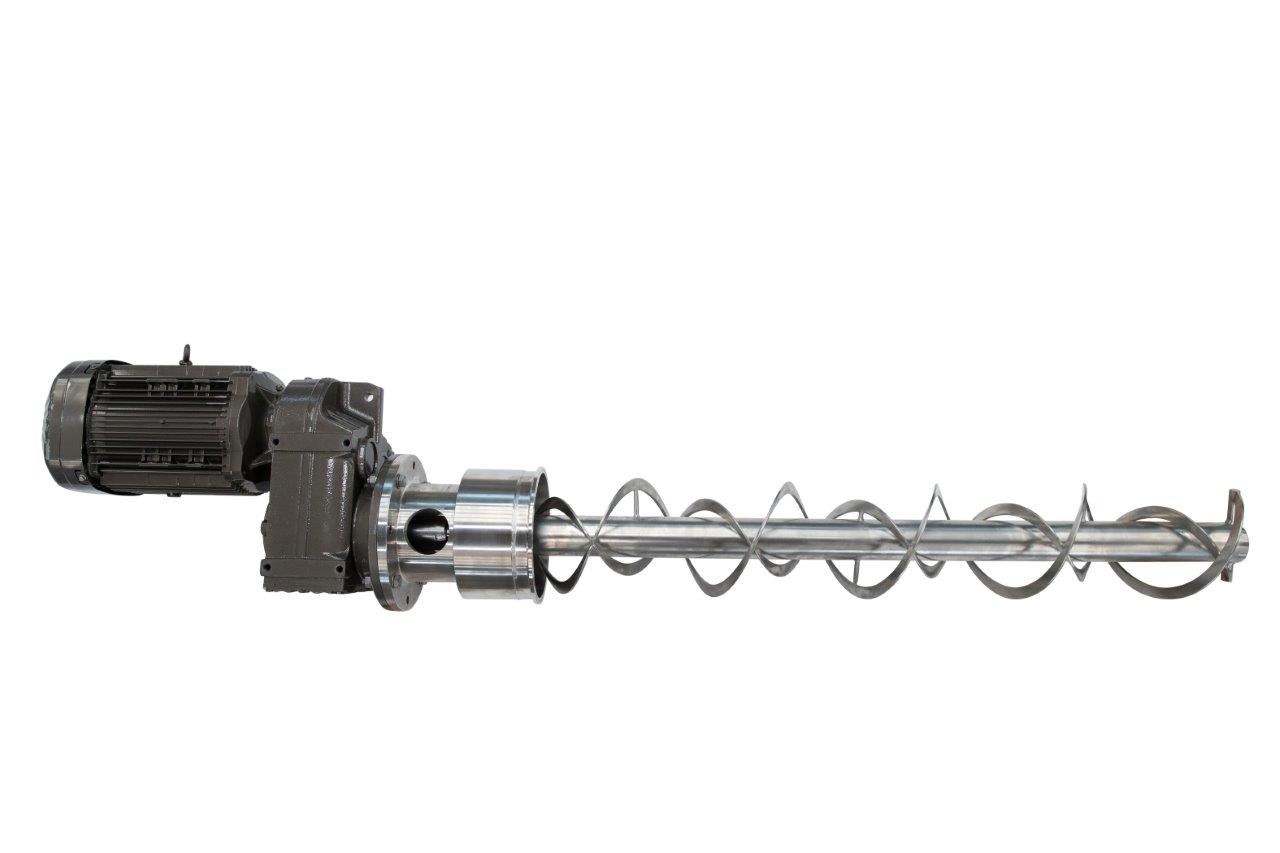

- Specially designed mixing flights give a thorough mix with minimal shear

- Built in AISI 304/316 stainless steel

- Easy to change from one fruit blend to another, plus fully CIP-able to maintain your plant in a hygienic condition.

- Fully automated with accurate control on blend ratios and product recipes

- Skid-mounted and pre-wired for easy installation

- Mixing fruit pieces or puree into a viscious-base

- Yoghurt

- Plant-based yoghurt (Coconut, Almond, Oat, Soy etc)

- Fruit hopper or debagging table for fruit supply

- Mobile version

Thermaflo Ingredient Mixing/Blending

Capacity: Any, please let us know your requirements

Dosing Accuracy: depending on your requirements we will use:

- Load cells

- Flow meters

- Level sensors

- Or a combination of the above

Construction: AISI 304 & 316 with other materials as an option

- From powder blending, wet milling, high-shearing and hydration of your ingredient we accurately build your product mix for further processing.

- Bespoke design to match your exact requirement

- CIP compatible

- Skid-mounted and pre-wired for easy installation

Any liquid food ingredient addition for human or pet consumption. Eg:

- Ice cream mix

- Beverage blending

- Yoghurt ingredient mixing and dosing

- Oil dosing

- Ingredient hydration

- etc

We will design to suit your process.

- CIP pump

- Data logging of process history for quality control

- Electronic control panel with colour touch screen

- For corrosive products, we can use titanium and/or duplex 2205 stainless steel

- Semi-automated or fully automated

- Mobile versions

Manufactured By Thermaflo NZ

Using our extensive experience and expertise, the Thermaflo team will design and fabricate a blending, mixing & dosing plant specifically for your application.

Our equipment is designed by our in house team of process engineers, and fabricated at our workshop by our mechanical and industrial electrical teams.