Bottle Fillers

Filmatic bottle filling machines meet the most stringent quality and hygiene requirements matched with high performance and flexibility.

The machines range from semi-automatic filling machines to suit small to medium scale through to fully automatic rotary bottle filling machines for large production requirements.

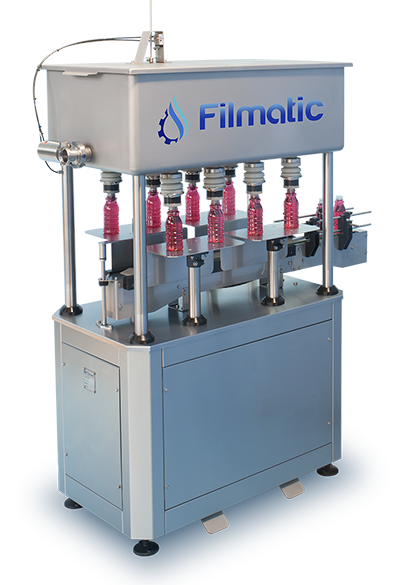

Filmatic Semi-Automatic Bottle Fillers

Filling volume: 250ml – 5L

Bottle filling rates: 190 to 2,300 bottles per hour (depending on bottle size)

Filling Methods: Level Filling, Time filling

Suitable for Filling: Non – viscous products such as water, milk, juice, ice tea, plant-based milk etc.

- Level fill accuracy can be adjusted manually and set once to achieve the same results every time

- The fillers have very few moving parts which means minimal maintenance

- Filling levels in each bottle can also be changed by inserting or removing spacers on the valves

- Non – viscous milk products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy milk etc)

- Juice (vegetable & fruit)

- Still beverages (ice tea, tonics, wine etc.)

- Water

- Can be fitted with a piston pump filling system for semi-viscious products like olive oil or other edible oils.

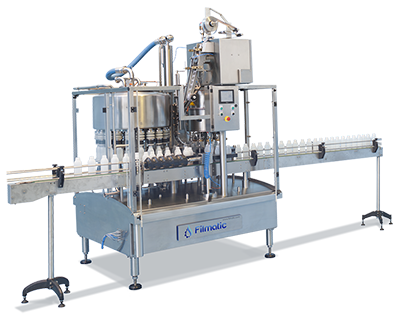

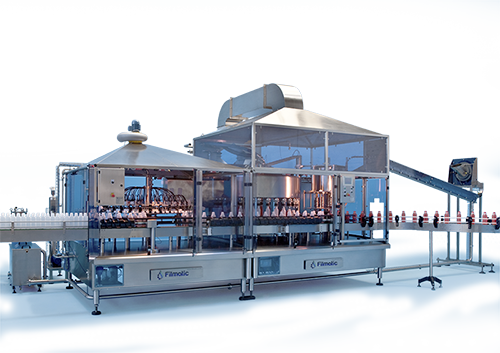

Filmatic Rotary Level Bottle Fillers

Suitable to Fill Bottles: 250ml – 5000ml

Configurations: 8 filling heads to 66 filling heads (model dependent)

Bottle handling: Neck or Base (model dependent)

Bottle filling rates: 1000 to 48,000 bottles per hour (dependent on bottle size)

Filling Temperatures: 4 Deg C – Any

Closing Types: Heat Seal, Screw Cap (28-38mm), Sports Cap (28mm)

Suitable for Filling: Non – viscous products such as water, milk, juice, ice tea, edible oil (by adding vacuum valves) etc.

Hygienic Options: Available

- Non – viscous products such as

- Water

- Milk

- Ice tea

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Vacuum valves can be added to fill edible oils

Filmatic Rotary Piston Bottle Fillers

Suitable to Fill Bottles: 250ml – 5000ml

Configurations: 8 filling heads to 30 filling heads (model dependent)

Bottle filling rates: 20 to 300 bottles per minute (dependent on bottle size)

Suitable for Filling: Viscous products such as mayonnaise, honey, edible oil, sauces, industrial fluids such as motor oils. Also suitable for high foam products through special filling nozzle / piston design.

Viscous products such as

- Mayonnaise

- Edible oil

- Sauces/condiments/spreads

- Honey

- And industrial fluids such as motor oils

High foam products cab be catered for through special filling nozzle / piston design.

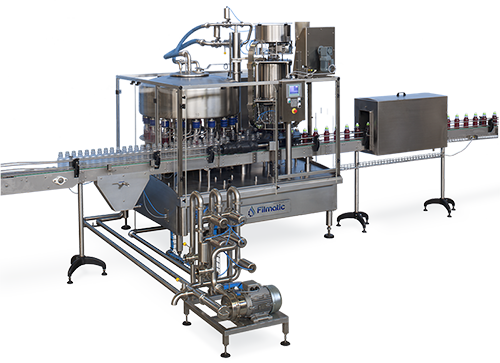

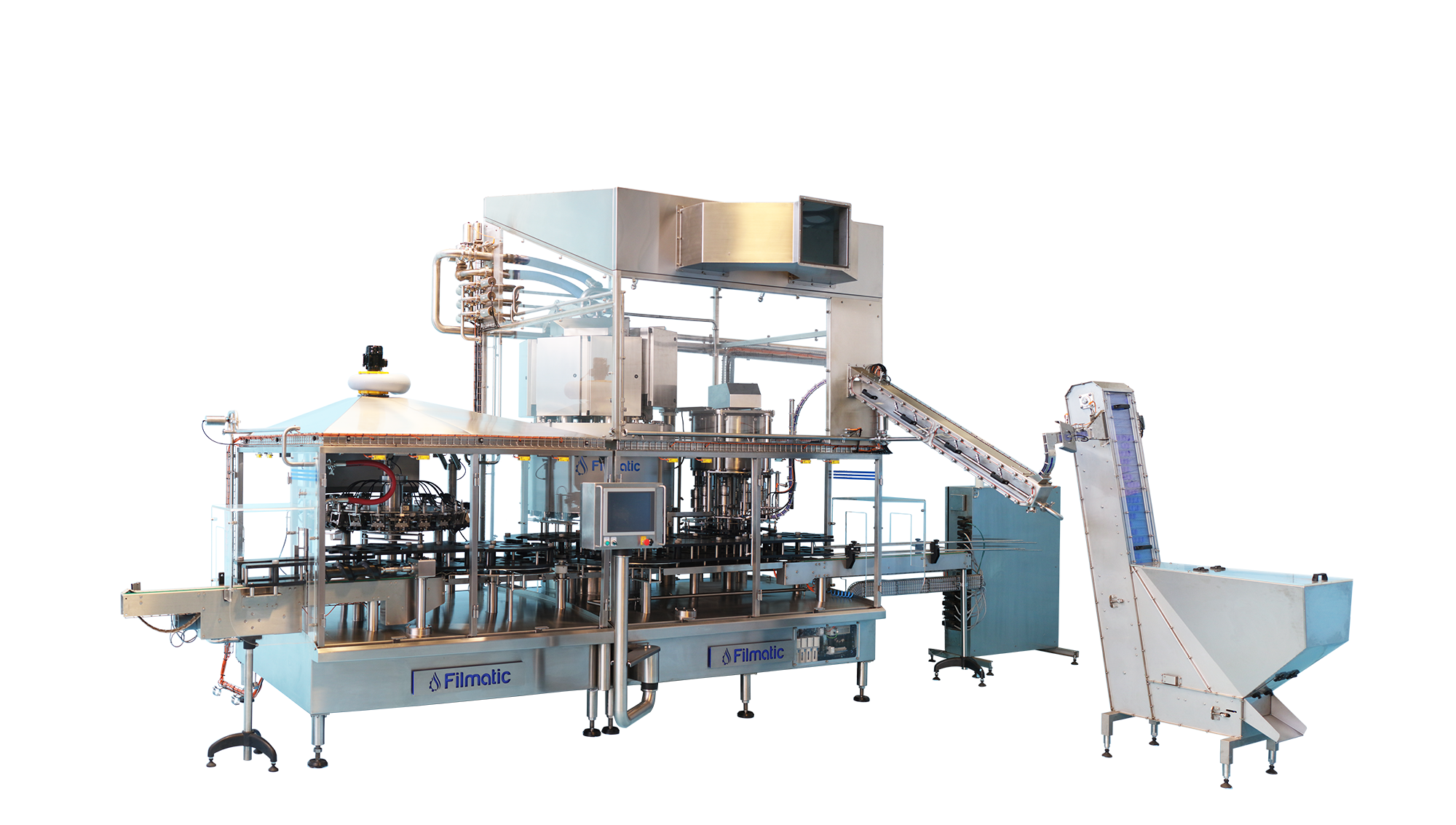

Filmatic Rotary Nett-Weigh Bottle Fillers

Suitable to Fill Bottles: 250ml – 5000ml

Configurations: 8 filling heads to 36 filling heads (model dependent)

Bottle filling rates: 50 to 400 bottles per minute (dependent on bottle size)

Suitable for Filling: High value products, i.e fresh milk, where precice filling accuracy is required.

- Highly accurate non-contact filling

- High speed filling with low foaming due to pressurized supply system and a continually variable flow rate filling valve

- Equipped with a highly effective closed loop CIP system

- Accommodates up to 3 different cap sizes and formats on 1 machine

- Fresh Milk

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Automatic lubrication

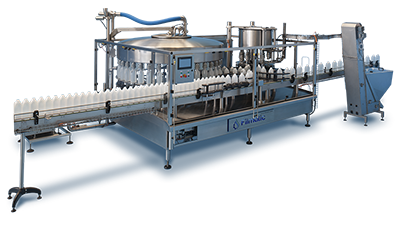

Filmatic Linear Pump Bottle Fillers

Suitable to Fill Bottles: 500ml – 5L

Configurations: Up to 12 filling heads (model dependent)

Bottle filling rates: 360 to 3,900 bottles per hour (dependent on bottle size)

Suitable for Filling: Viscous products such as mayonnaise, honey, jams, edible oil, sauces, Household and industrial fluids such as shampoo and motor oils. Also suitable for high foam products through special filling nozzle / piston design.

- Suitable to fill glass as well as PET and HDPE bottles

High viscosity and foaming products such as

- Syrups

- Drinking yogurt

- Sunflower and olive oil

- Honey

- Chocolate spread

- Marmalade, jams

- Tomato sauce, mayonnaise, salad dressing, mustard

- Mousse

- Household detergents

- Fabric softeners

- Washing liquids

- Floor cleaners

- Disinfectants

- Shampoos and hair products

- Vaseline and petroleum jellies

- Liquid waxes

- Linseed oil

- Resins

- Motor oils

- Windscreen products

- Anti-freeze,

- Lubrication oils

- Insecticides, and fungicides

- Full CIP system available

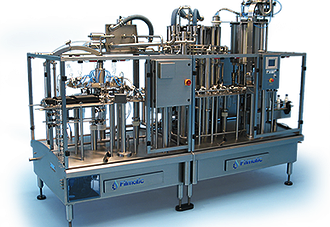

Filmatic ESL (Extended Shelf Life) Bottle Fillers

Suitable to Fill Bottles: 250ml – 5000ml

Configurations: variable depending on product requirements

Models: ESL Level Fillers, ESL Piston Fillers, ESL Nett-Weigh Fillers

Bottle filling rates: variable (dependent on product bottle size)

Suitable for Filling: High value products, i.e fresh milk, where precice filling accuracy is required.

- High value products such as milk, juice or sauces.

- Anti foaming and anti-spillage measures are available

Manufactured By Filmatic

Since they started in 1979, Filmatic has been driven by quality, excellent service and cost effectiveness.

The core line of Filmatic’s product is the manufacturing of liquid filling and packaging equipment.

With their years of experiencem they have a special focus on continual R&D, that allows them to fill challenging/foamy liquids like milk or window cleaner with ease.