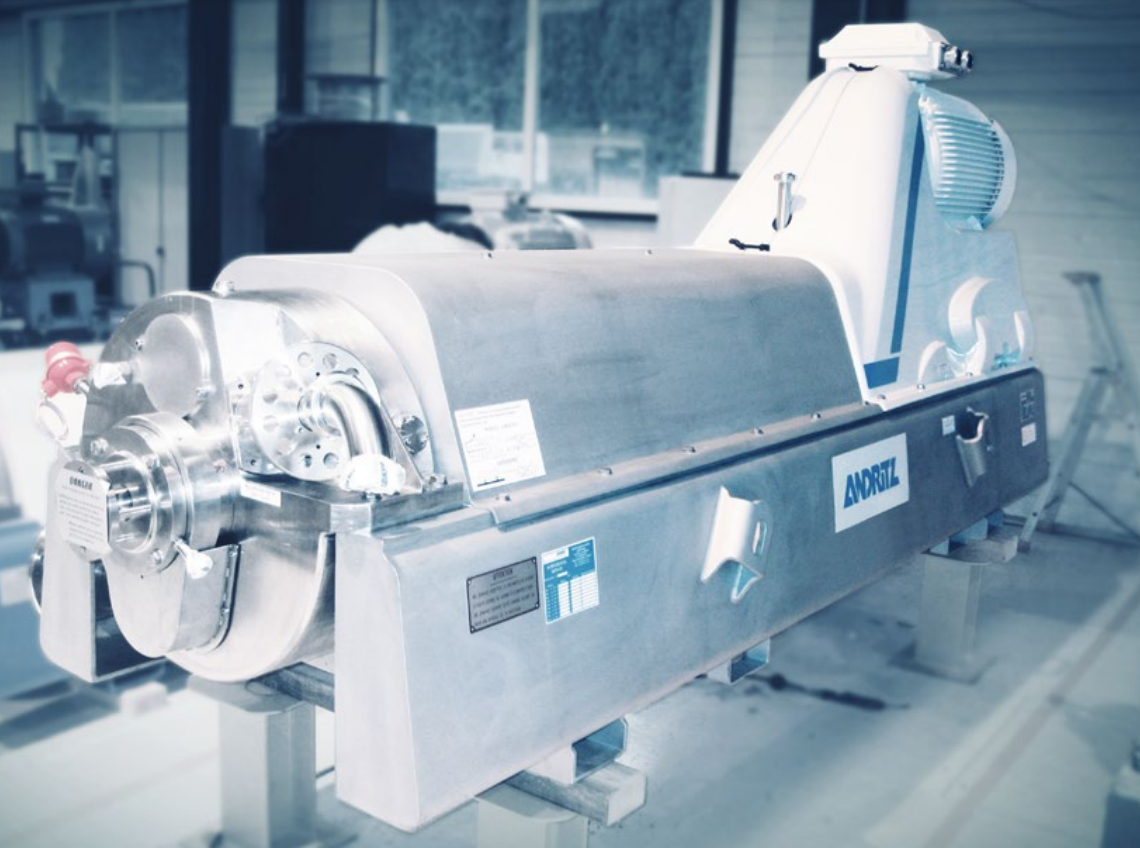

Decanters

The Andritz decanter centrifuge series F is specially designed to meet the strict requirements of the food and beverage industries.

Andritz has considerable experience in seperation with over 15,000 decanters installed around the world.

Decanters

Andritz Decanter Centrifuge F

Models Available: 5

Feed Capacity: 1000L/hr – 15,000 L/hr (depending on model)

G-force: 3,500G

- Gentle product handling with a special feed chamber

- Long service life due to robust design and high-grade materials

- Low maintenance cost and easy dismantling with unique inline design

- Low oxygen pick-up due to discharge under pressure from a hermetically sealed chamber

- Protection against abrasion (replaceable tungsten carbide wear parts or special material on scroll flight)

- Beverage extraction (wine, juices)

- Beverage solid reduction (wine, juices, plant-based milk)

- Dairy (casein, lactose, calcium phosphate)

- Oil and fats (olive oil — two and three phases, animal blood, animal fat)

- Green chemicals (starch, proteins, bioethanol, vinasses K2SO4)

- Sanitary option – designed for applications where maximum cleanliness is required.

-

Rotor design can be tailor made for specific applications

Manufactured By Andritz

ANDRITZ SEPARATION, will get to know your process and pay attention to your needs. Each application has its own designed decanter with its equipment by feature to reach the best performances and meet top level requirements.