Tub & Cup Fillers

Filmatic & Trepko tub & cup filllers allow for precision dosing of highly viscous product.

Suitable for filling precise quantities of yoghurt, cream cheese, butter, spreads, and other highly viscous products into tubs.

The machines have the ability to fill multi-layered products in one filling cycle.

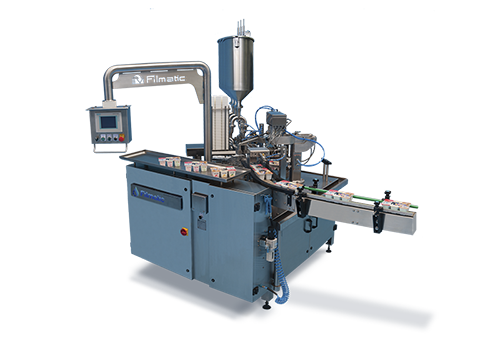

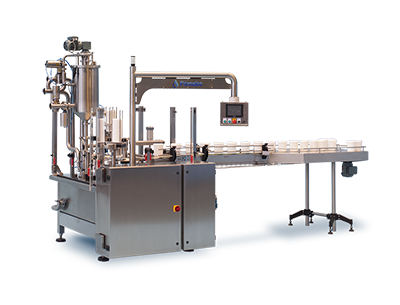

Filmatic Index Tub Fillers

Suitable to Fill Tubs/Cups: 175ml – 1000ml or six packs in either 75g or 100g

Configurations: one to three filling lanes (model dependent)

Tub/cup filling rates: 20 to 95 cups per minute (dependent on size)

Closing Types: various – including snap cap, over cap and foil

Suitable for Filling: Viscous products such as yoghurt, butter, margarine, desserts etc.

- Can accommodate wet or dry product dosing and corner cup configurations (excluding FXV6 – six pack filler).

- No container, no fill system to minimize product wastage

- Cream cheese

- Cream

- Yoghurt

- Desserts

- Cottage Cheese

- Other viscous products

- Capping options include: Foil heat seal – Snap cap – over cap (excl FXV6 model)

Trepko Rotary Tub Fillers

Suitable to Fill Tubs/Cups: 100ml – 1000ml – but can be customised

Configurations: one to six filling lanes (model dependent)

Tub/cup filling rates: From 2,400 to 14,000 cups per hour (dependent on size)

Closing Types: various – including snap cap, over cap and foil

Suitable for Filling: Viscous products such as yoghurt, butter, custard, sauces, margarine, desserts etc.

- Designed with flexibility in mind, available for a variety of cups and containers, and suited to filling a variety of products

- Can accommodate wet or dry product dosing including fruit puree/sauces swirls

- Various hygiene options including laminar flow cabins, UV radiation cups & lids, chemical sterilisations and gas flushes.

- Cream cheese

- Cream

- Yoghurt

- Desserts incl products with vertical, horizontal and twisted layers

- Cottage Cheese

- Other viscous products

- processed cheese

- Custard

- Butter/margarine

- Spreads

- Pâté

- Jam/marmalade/honey/conserve

- Ketchup/ sauces/puree/mustard/mayonnaise

- Salads

- CIP/SIP of dosers

- sterile air cabin

- vacuum cleaning

- gas flush

- chemical sterilization

- seal check and elimination of defective cups

- cup deionization

- UV radiation of cup and foils

- stack feeding magazines for cups and lids

- sledge magazine for pre cut foils

- automatic volume adjustment

- pre- or post dosing

- dry filling

- compensator

- scroll chute hopper

- horizontal or vertical agitators

- heat-sealed pre-cut foil

- foil from reel

- vacuum heat-sealing

- snap on lids

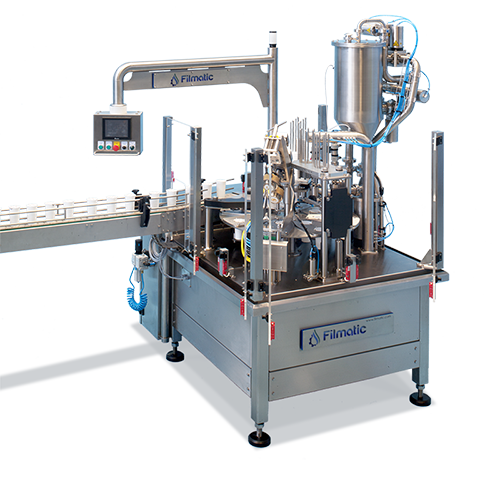

Trepko Carousel Tub/Cup Fillers

Models available: 2

Configurations: 1 or 2 lanes

Output: Up to 2500 to 5000 cups per hour (dependent on model)

Suitable for Filling: multi-layer dessert products or yoghurt with fruit puree/sauce/dry ingredients

- Designed around a carousel principle for handling pre-formed containers and provides a medium to high speed production output

- Options for several multi-fill applications with additional depositors for liquid, semi-liquid, dry products or simple hand placement areas.

- Ideal for creating sophisticated multi-layer products, especially desserts.

- Multilayer products, such as desserts or yoghurts with fruit pulp/sauce and/or dry ingredients

- Closing options are also available such as pre-cut and foil from reel or snap-on lids

- Magazine buffers for cups and lids are available to aid the operator and ensure reliable production levels

- ULTRACLEAN version available

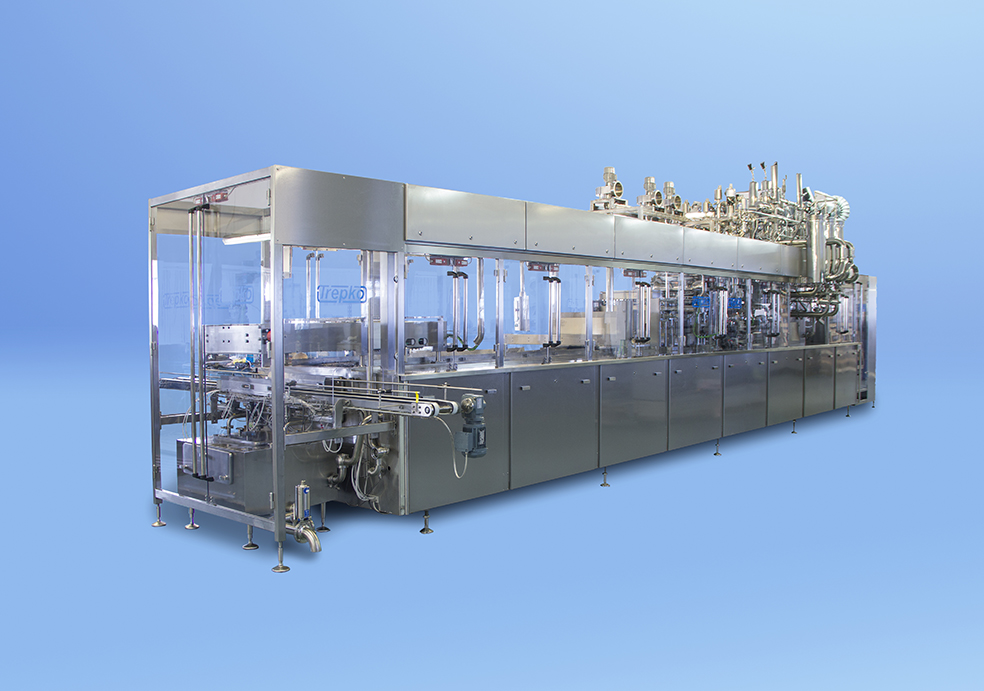

Trepko Inline Aseptic Filling Machine

Number of filler points: Dependent on customer requirements

Number of lanes: Dependent on customer requirements. The standard range comprises of 1, 2, 3, 4, 6, 8 and 10 lanes, single or double index

Maxmum output (cups/h): Dependent on the number of lanes and products being filled

Max. cup dimensions (mm): Up to 200 mm dia

Max. cup height (mm): Up to 130 mm

- The 100 series is suitable for a variety of products including cups and straight-sided containers,

- The modular design allows for bespoke layouts,

- We can configure the machine to meet your exact specifications.

- milk

- cream

- yoghurt

- kefir

- cream cheese

- processed cheese

- mousse

- desserts

- quark

- cottage cheese, (incl with fruit pulp)

- butter/margarine

- jam, honey, conserve

- mayonnaise, dressing, ketchup, sauces

- salads

- pâte

- lard

- pet food

- spreads

- shortening

- Choose from three levels of hygiene: Standard / Ultra Clean / Aseptic

- Closing Options: Foil from reel or vacuum heat-sealing

- Dry fillers

- Pick & place unit

- Pre- and after dosing

Trepko Semi-Automatic Tub Filling and Closing Machines

Output: Up to 720 – 1200 tubs or cups/hr (dependent on operator)

Suitable for Filling: Viscous products, such as yoghurt, cream cheese, desserts etc.

- Semi-automatic tub/cup filler

- The automatic features of these machines are: lid placement, heat-sealing or closing by plastic snap-on lid and are pneumatically driven.

- All change parts are designed for quick changeover times to minimise downtime

- This is a cost-effective option for customers whose required output does not warrant a fully automatic machine

- Cream cheese

- Cream

- Yoghurt

- Desserts

- Cottage Cheese

- Other viscous products

- A different frame size is available for larger containers

- Can be equipped with an automatic product doser

- Can be supplied with change parts for different container sizes,

Manufactured By Trepko & Filmatic

Trepko is a truly international manufacturer, based in Denmark with sites in Poland, the United Kingdom and Brazil, while Filmatic has its manufacturing base in South Africa.

The brands are so complementary that Filmatic became a subsidiary of the Trepko group in 2015. So although they are two different brands, they are in effect, the same company with shared technology.

Both companies have considerable expertise in filling high-value and delicate products, so they have a strong emphasis on gentle product handling and avoiding waste/spillage.