Container Plants

Container plants are ideally suited to small scale/start-up plants and CIP systems for bulk liquid transport tankers where hygiene is important

Purchasing a container plant will help keep your costs down, while you begin production and therefore entry into your target market while allowing for future flexibility

The beauty of a containerised process plant is that you receive a specifically designed, fit for purpose process plant that is housed in a fully hygienic, fitted out container that is built to meet the highest international food grade standards.

Container Plants

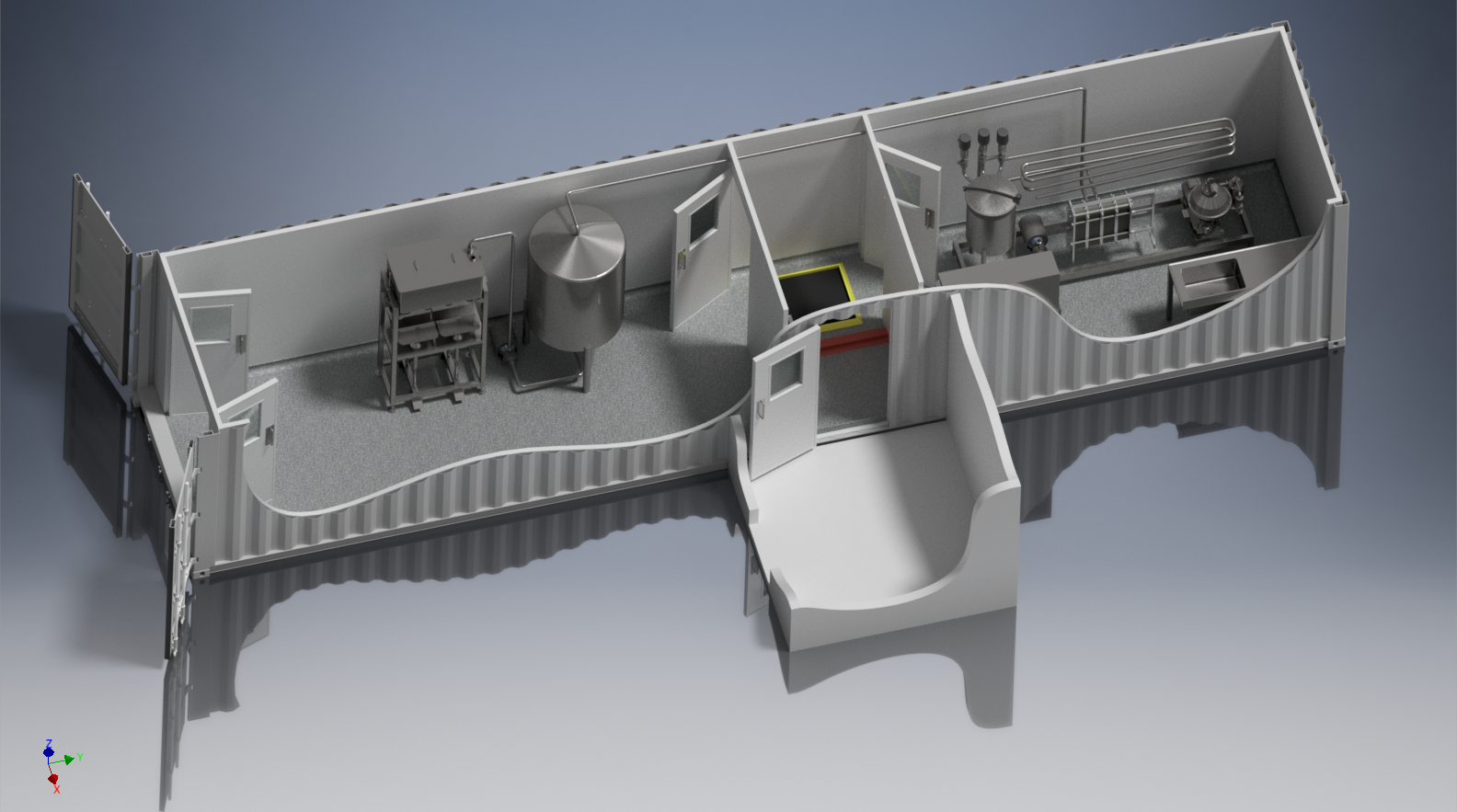

Thermaflo Container Plant

Size: 20 or 40 foot container

External elements required outside of container: water connection, boiler, chiller and raw product tank

Boiler options: Diesel or LPG

Fitout: Food grade standards

- Turnkey hygienic plant

- Custom designed for your process

- Lower setup costs

- Minimal site work required

Ideal for small-scale production of:

- Milk

- Cheese

- Juice

- Yoghurts

- Plant-based dairy alternatives

- Other beverages or liquid food

- Liquid cosmetics (eg. skin cream)

- Nutraceutical products

- Custom designed for your process and requirements

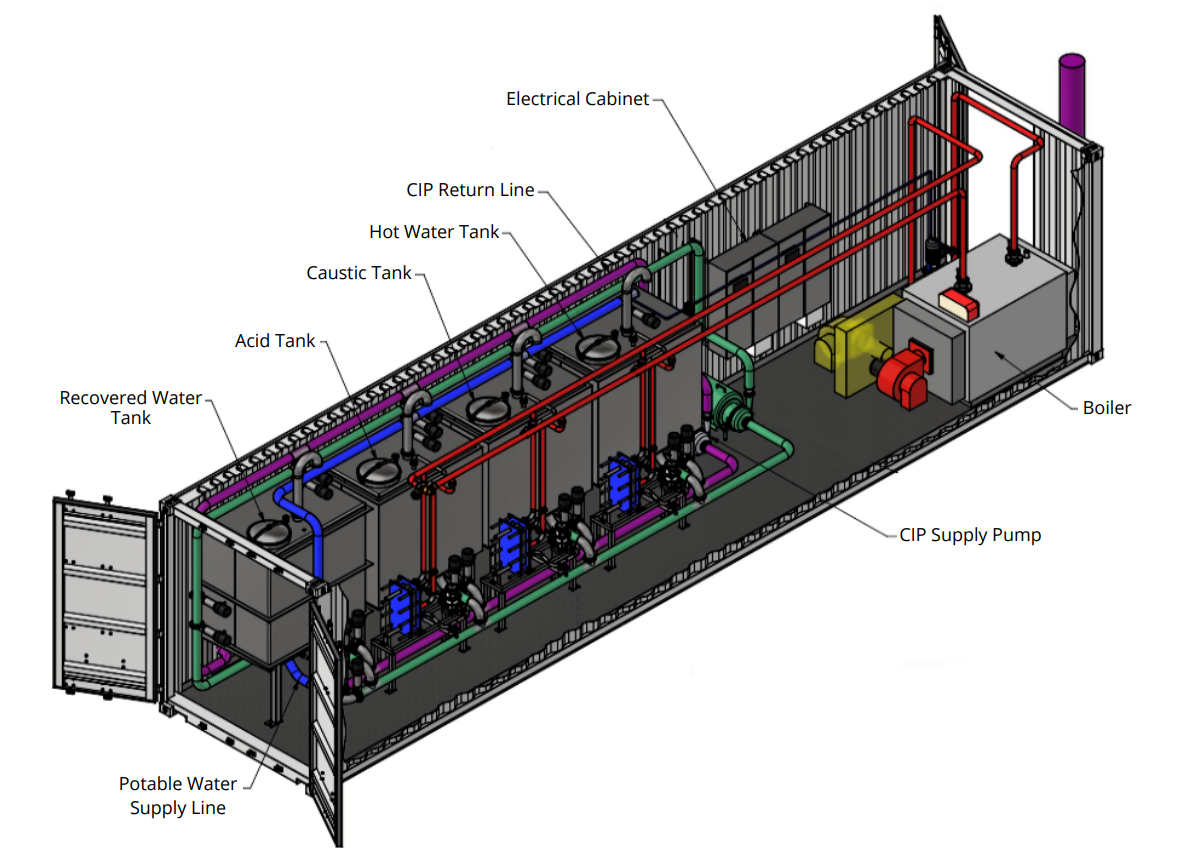

Thermaflo CIP Container Plant

CIP Lines: 1

Flowrates: Up to 100,000 L/hr

Wash temperature: Up to 80 dec C

Tanks: Acid, caustic, hot water and water recovery

Boiler: LPG or Diesel

Control: Fully automatic with touchscreen HMI

Software: Data capture and trending included

- Plug & Play tanker wash solution

- Customised to suit your wash requirements

- Enhanced driver/operator safety

- Multiple wash cycles can be programmed in to control panel.

- Up to 30kL tanker and trailer in single wash

- 2nd CIP line can be added in to wash two tankers and trailers in a single wash

Manufactured By Thermaflo NZ

Our CIP kitchens will deliver the correct cleaning variables of time, temperature, and chemical concentration. They are designed to reduce chemical and water usage, lower cleaning times and reduce your overall cleaning costs, as well as enhancing operator safety.

Our equipment is designed by our in house team of process engineers, and fabricated at our workshop by our mechanical and industrial electrical teams.