Ice Cream Equipment

We have worked on many ice cream/gelato projects, from equipment and/or capacity upgrades, right through to the design, fabrication, and installation of complete plants.

Due to the wide variety of potential ingredients, we custom design each ice cream process. Starting with the mixing stage to ensure full hydration of the various components, and moving through heat treatment, homogenisation (if required), ageing, churning and finally filling.

Ice Cream Equipment

Thermaflo Ice Cream Mix Plant

Ice Cream Mix Preparation: 100L Per Batch – 10,000L Per Hour

Pasteurising Inlet Temperature: 4 Deg C – Any

Pasteurising Temperature: 73 Deg C – 90 Deg C

Pasteurising Outlet Temperature: Any – 4 Deg C For Ice Cream Mix

- Custom built plant designed specifically for your process and plant layout to best utilise the space that is available

- Suitable for small boutique processes right through to large commercial scale equipment

- Process steps can include:

- Ingredient mixing & hydration

- Heat Treatment (pasteurisation)

- Homogenisation (optional)

- Ageing tanks

- Churns

- Filling

- Ice Cream

- Gelato

- Frozen Yoghurt

- We also supply batch and continuous freezer churns as well as ice cream fillers to provide you a complete line.

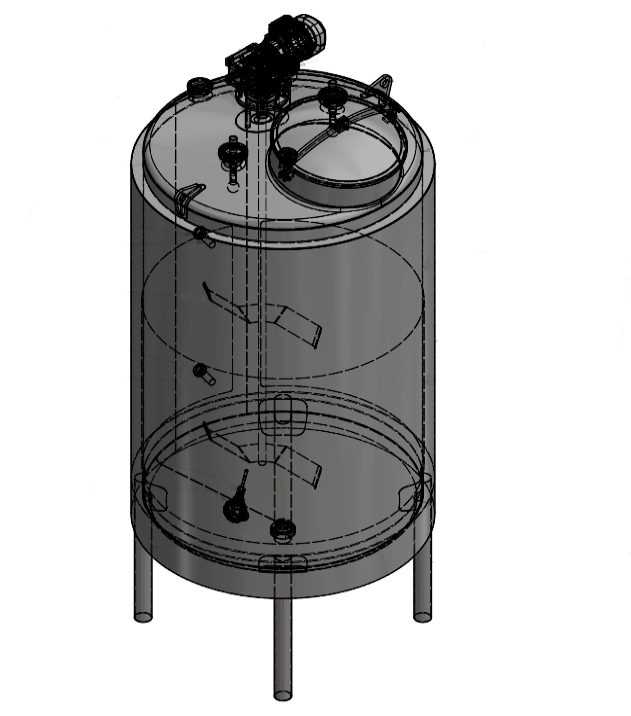

Thermaflo Ice Cream Ageing Tanks

Size: Any – size and volume specifically designed to suit the project’s requirements

Materials: Fabricated in the correct Stainless Steel grade (typically AISI 304/316) to suit the specific tanks application

Temperature: 4 deg C or less to ensure the milk fat has time to partially crystallize, and the protein stabilizers time to hydrate

- Ice Cream

- Gelato

- Frozen Yoghurt

- Designed to HSNO / pressure and/or Seismic Standards as required

- Semi automated or fully automated product infeed and forwarding

Manufactured By Thermaflo NZ

We have considerable experience in ice cream/gelato/frozen yogurt processes across Australasia. Due to the wide variety of ingredients that could be used, we pay particular attention to the mixing stage to ensure full hydration of the various components.

Our equipment is designed by our in house team of process engineers, and fabricated at our workshop by our mechanical and industrial electrical teams.