Membrane Filtration

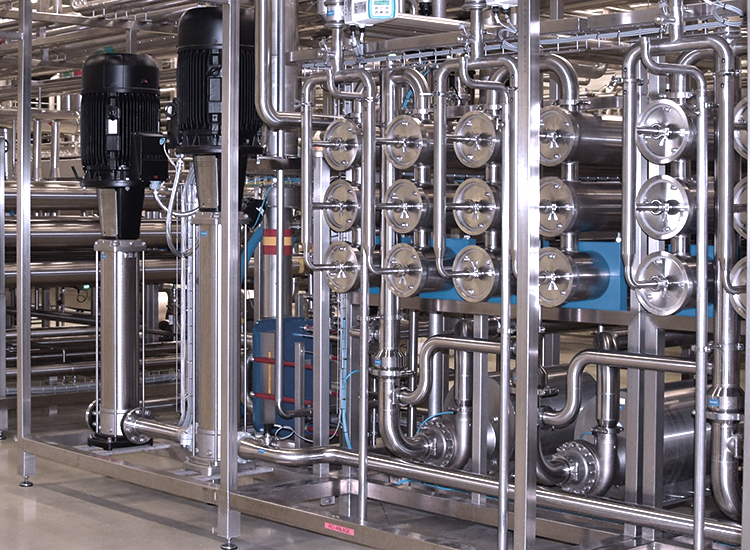

Through our partnership with MMS Membranes, we are able to supply you with a system that will sterilise, clarify, fractionalise, concentrate or purify depending on your requirements

Based on many years of experience, MMS provide detailed and application-specific advice on the possibilities of membrane applications.

Membrane Filtration

MMS Membrane Filtration Plants

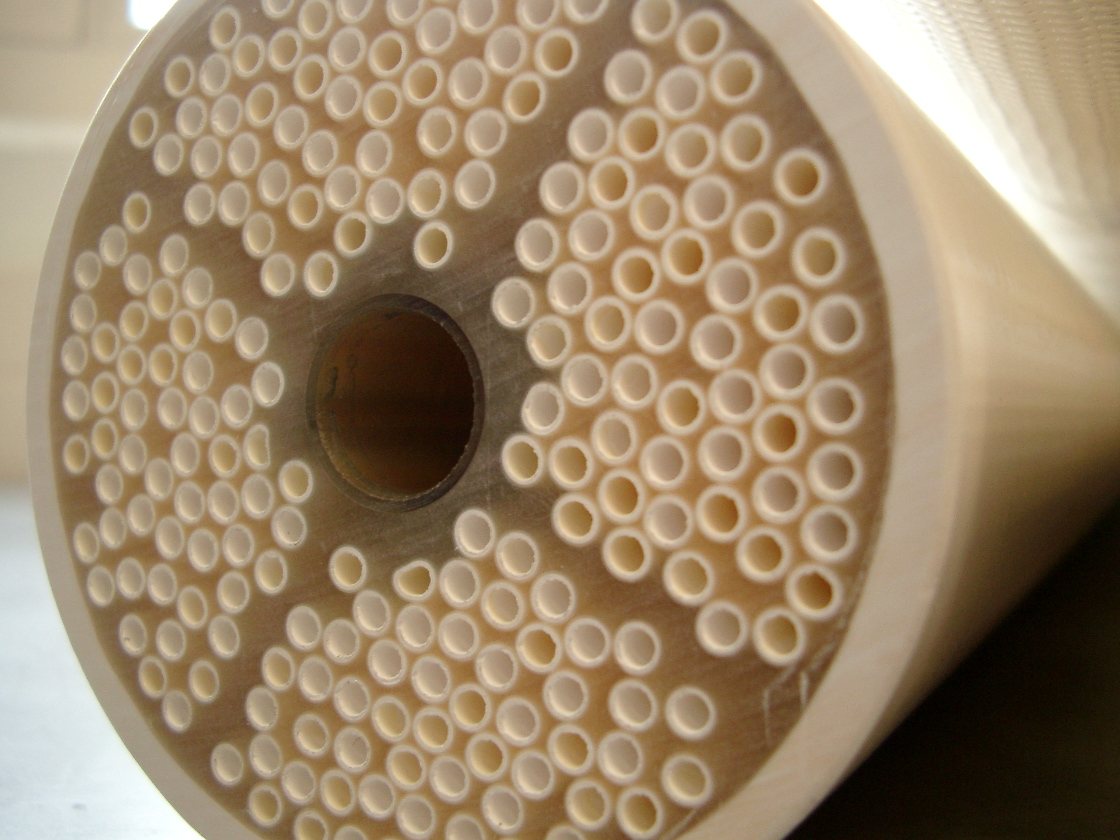

Membrane Technologies:

- Microfiltration – pore size ranging from 0.05 μm to 2 μm

- Ultrafiltration – pore sizes ranging from 0.1 μm to 0.01 μm

- Nanofiltration membranes pores sized from 0.001 μm to 0.01 μm

- Reverse osmosis (RO) – pore sizes range from 0.0001 μm to 0.001 μm

- Wide range of application across food and beverage processes, including concentration, clarificaiton and purification.

- Each plant is custom designed to your process and requirements.

Applications of Microfiltration:

- Sterilisation eg milk, whey, juice

- Purification eg Juice

- Concentration eg milk fat

Applications of Ultrafiltration:

- Concentration eg Whey proteins, juice, milk

- Fractionalisation eg oil from water

- Clarification eg wine, juice

Applications of Nanofiltration

- Part Demineralization and Concentration eg whey

- Concentration and Enrichment

Applications of Reverse Osmosis

- Concentration eg Milk, Whey, Lactose, Juice

- Purification eg water purificaiton for reuse or wastewater treatment

- Each system is custom designed to your process and requirements.

MMS BeerMax De-alcoholisaion Skid

Models available: 2

Capacity: 10 – 100hL / day (dependent on model)

Membrane Technology: Reverse Osmosis 8038

Membrane Area: 60 – 120m² (dependent on model)

Operating pressure: 25-40 bar

Working temperature: 5 – 10°C

Footprint: 2400 x 1000 x 2000 mm (L x W x H)

- Automated Cleaning in Place

- Full automation with easy to use touchscreen

- Low energy consumption

- Operates at low temperature to preserve taste

- Reduces alcohol content to <0.5% ABV

- Suitable for beer/wine/cider

Upgradeable – the BeerMAX 60 can double capacity to the larger 120 model through the addition of extra RO membranes

MMS Lab Scale Membrane Systems

Number of membrane cells: 3 (total area 84cm 2)

Permeate flow rate: 1.5 – 7.5 ml/min (for flux values of 10 – 50 Lm -2 h-1)

Crossflow: 0.5 – 2 L/min (equivalent to approx. 0.5 – 4 m/s)

System Hold up Volume: 50ml

Pressure Rating: PN40, driving pressure created by compressed N2

Temperature Rating: 5 – 80 °C (polystat required)

Dimensions: 700 x 510 x 510 (mm)

Weight: 50Kg

- Easy-to-use batch laboratory membrane device for microfiltration, ultrafiltration, nanofiltration and reverse osmosis operations

- Cooling/heating jacket on tank for temperature regulation

- High operating pressures

- HMI interface with data logging

- Rapid screening of up to three membranes simultaneously

- Speed control of circulation pump for variable membrane crossflow velocity

- Wide range of membranes available

- Diafiltration Kit

- Membrane Cutting Tool

- Membrane Sheets Cut-offs

- Solvent Kit

Manufactured By MMS Membranes

For more than 25 years, MMS AG has been developing and designing membrane processes together with its customers and successfully implementing them on an industrial scale.

Since its foundation in 1995 MMS has been involved in hundreds of turn-key membrane projects for industries such as dairy and food processing, as well as for the pharmaceutical and biotechnology sectors.