Yoghurt Equipment

Whether you are looking for a traditional pot set or stirred yoghurt, or kefir, we will supply the equipment and technical design needed for your product.

We have a wealth of experience in both dairy and plant based yoghurt. We can help with supplying and integrating individual items of equipment through to designing, and fabricating plant upgrades or new greenfield plants.

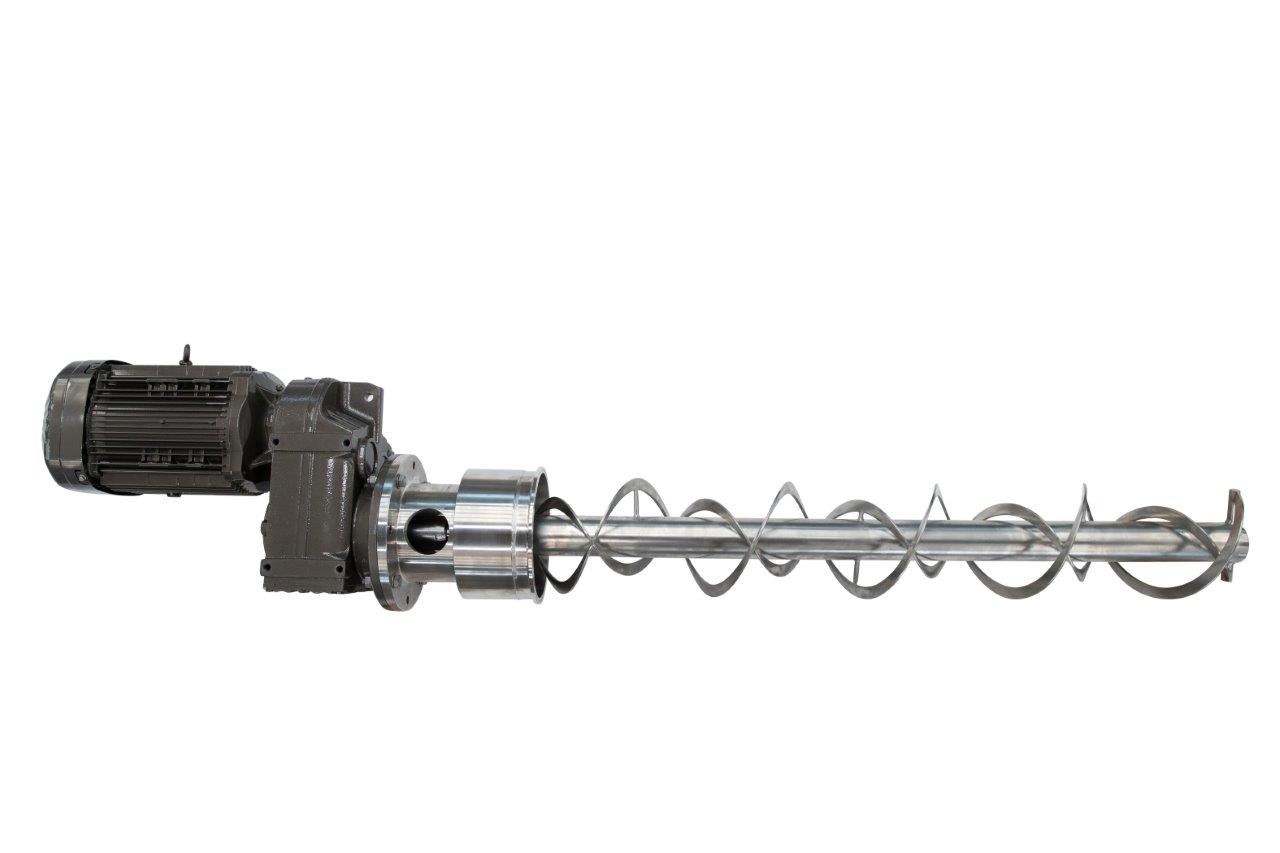

Thermaflo Yoghurt Blending/Mixing

Size: Any, please let us know your requirements

Materials: All fabricated in the correct Stainless Steel grade to suit that specific application (Typically AISI 304/316)

- Pot set yoghurt

- Stirred yoghurt

- Drinking yoghurt

- Greek yoghurt etc

- Designed to suit your process

Thermaflo Yoghurt Pasteuriser

Pasteuriser: Batch or HTST

Batch Size 150L Per Batch – 10,000L Per Batch

Yoghurt Milk Mix Temperature 4 Deg C – 25 Deg C (approx)

Protein Denature Temperature 80 Deg C – 95 Deg C (approx)

Outlet Temperature 25 Deg C – 45 Deg C (approx)

- We design and manufacture both HTST and Batch pasteurisers to suit your yoghurt volumes and temperature profiles.

- Pot set yoghurt

- Stirred yoghurt

- Drinking yoghurt

- Greek yoghurt etc

- Can be designed to suit your site-specific requirements

- CIP pump

- Data logging of process history for quality control

- Electronic control panel with colour touch screen for easy recipe selection and fine tuning

Thermaflo Incubation Tanks

Size: Any, please let us know your requirements

Materials: All fabricated in the correct Stainless Steel grade to suit that specific application (typically AISI304/316)

- Proven method of inline cooling stired yoghurts – to control the pH

- Yoghurt

- Dairy

- Plant based

- Or any cultured liquid food

- Data logging for quality control

- Scraped surface agitation

Thermaflo Fruit Dosing Machines

Capacity: From Up to 2000L/hr to Up to 6000L/hr

Instrumentation and Control Panel:

- Yoghurt and Fruit Line Flow Meters

- VSD on pumps

- Level transmitter on balance tank

- Full PLC and HMI

- CIP program dedicated to the mixer

- Water flush program

- VSD controlled dynamic mixer motor

Construction: Skid and framework made with stainless steel 304, pipework, chambers and balance tank made with 316 stainless steel

Pumps: Stainless steel 316 sanitary pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

- Specially designed mixing flights give a thorough mix with minimal shear

- Built in AISI 304/316 stainless steel

- Easy to change from one fruit blend to another, plus fully CIP-able to maintain your plant in a hygienic condition.

- Fully automated with accurate control on blend ratios and product recipes

- Skid-mounted and pre-wired for easy installation

- Mixing fruit pieces or puree into a viscous-base

- Yoghurt

- Plant-based yoghurt (Coconut, Almond, Oat, Soy etc)

- Fruit hopper or debagging table for fruit supply

- Mobile version

Manufactured By Thermaflo NZ

We have been designing and fabricating pasteurisers since 1992. We supply top quality, efficient pasteurisers that are specifically designed to produce repeatable results that meet your process needs.

Our equipment is designed by our in house team of process engineers, and fabricated at our workshop by our mechanical and industrial electrical teams.

Over time Thermaflo worked with us to establish the specifications we needed the HTST Pasteuriser built to, as we required a broad temperature profile. We signed off on their final design, which they proceeded to build, deliver and commission.

The end result is that we have managed to meet all our temperature profiles hence making the production process of our fresh milk, cheeses and yoghurts a lot easier.

Thermaflo have always been quick to respond to any queries and have worked hard to deliver a successful project.