CIP Kitchens

Thermaflo offers four standard CIP designs, but all can be customised to suit the hygiene requirements of your plant.

Our systems have been used for many years in even the most demanding hygiene environments, pharmaceutical and dairy.

Thermaflo CIP Kitchens

Thermaflo Single-Use Manual CIP Kitchen

Tanks required: 1

Tank Size: 500L – 1000L +

Instrumentation and Control Panel:

-

- Push Button Controls

- Visual Indicators for Operator

- Temperature Transmitter

Construction: Cone based, insulated, Tank and Pipes made with stainless steel 316

Pumps: Stainless steel 316 sanitary design centrifugal pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

- Low Capacity, small footprint – Compact self contained unit

- Suit single circuits with infrequent cycles

- Internal element heated system

- Easy to use, push button control cabinet

- Food and beverage plant cleaning

- Dairy

- Milk

- Cheese

- Ice Cream

- Yoghurt

- Juices

- Sauces & Condiments

- Plant based dairy alternatives

- Breweries/Wineries

- Edible Oils

- Dairy

- Pharmaceutical

- Pet food

- Chemical

- Mobile Version

Thermaflo OnDemand Basic CIP Kitchen

Tanks required: 1

Tank Size: 500L – 5000L

Instrumentation and Control Panel:

-

- Inline and in tank conductivity meters

- Flow meters

- VSD on pumps

- Level transmitter

- Temperature transmitter

- Full PCC and HMI

- 21 step CIP program customised to site requirements

- Automatic Solids Discharge

Construction: Cone based, insulated, Tank and Pipes made with stainless steel 316

Pumps: Stainless steel 316 sanitary design centrifugal pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

- High Capacity, with a reduced footprint

- Suits single circuits with scheduled cycles

- Food and beverage plant cleaning

- Dairy

- Milk

- Cheese

- Ice Cream

- Yoghurt

- Juices

- Sauces & Condiments

- Plant based dairy alternatives

- Breweries/Wineries

- Edible Oils

- Dairy

- Pharmaceutical

- Pet food

- Chemical

- Rinse recovery (additional tank required)

- Potable stored water supply (additional tank required) for sites with limited water supply

- Service Support with remote trouble shooting service

Thermaflo Max OnDemand CIP Kitchen

Tanks required: 2

Tank Size: 500L – 5000L

Instrumentation and Control Panel:

-

- Inline and in tank conductivity meters

- Flow meters

- VSD on pumps

- Level transmitter

- Temperature transmitter

- Full PCC and HMI

- 21 step CIP program customised to site requirements

- Automatic Solids Discharge

Construction: Cone based, insulated, Tank and Pipes made with stainless steel 316

Pumps: Stainless steel 316 sanitary design centrifugal pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

- Separate Caustic and Acid Tank

- Fully automated 21 step CIP program including sanitiser dosing

- Recovers as much CIP solution as possible

- Always delivers CIP at the correct temperature, chemical strength and flow rate to ensure optimal plant hygiene

- Fully insulated tanks and heated on demand

- Chemical dosing kept optimal with loop and inline conductivity meter

- Supplies multiple circuits with scheduled cycles

- Food and beverage plant cleaning

- Dairy

- Milk

- Cheese

- Ice Cream

- Yoghurt

- Juices

- Sauces & Condiments

- Plant based dairy alternatives

- Breweries/Wineries

- Edible Oils

- Dairy

- Pharmaceutical

- Pet food

- Chemical

- Rinse recovery (additional tank required)

- Potable stored water supply (additional tank required) for sites with limited water supply

- Service Support with remote trouble shooting service

Thermaflo Max EverReady CIP Kitchen

Tanks required: 2 (Rinse recovery or potable water tank can be added as an option)

Tank Size: 500L – 5000L

Instrumentation and Control Panel:

-

- Inline and in tank conductivity meters

- Flow meters

- VSD on pumps

- Level transmitter

- Temperature transmitter

- Full PCC and HMI

- 21 step CIP program customised to site requirements

- Automatic Solids Discharge

Construction: Cone based, insulated, Tank and Pipes made with stainless steel 316

Pumps: Stainless steel 316 sanitary design centrifugal pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Electrical Supply: 380/415V, 3 Phase, 50 Hertz

- High/constant demand CIP solution

- Separate Caustic and Acid Tank

- Fully automated 21 step CIP program including sanitiser dosing

- Recovers as much CIP solution as possible

- Always delivers CIP at the correct temperature, chemical strength and flow rate to ensure optimal plant hygiene

- Fully insulated tanks and continuously heated

- Chemical dosing kept optimal with loop and inline conductivity meter

- Supplies multiple circuits with unscheduled cycles

- Food and beverage plant cleaning

- Dairy

- Milk

- Cheese

- Ice Cream

- Yoghurt

- Juices

- Sauces & Condiments

- Plant based dairy alternatives

- Breweries/Wineries

- Edible Oils

- Dairy

- Pharmaceutical

- Pet food

- Chemical

- Rinse recovery (additional tank required)

- Potable stored water supply (additional tank required) for sites with limited water supply

- Service Support with remote trouble shooting service

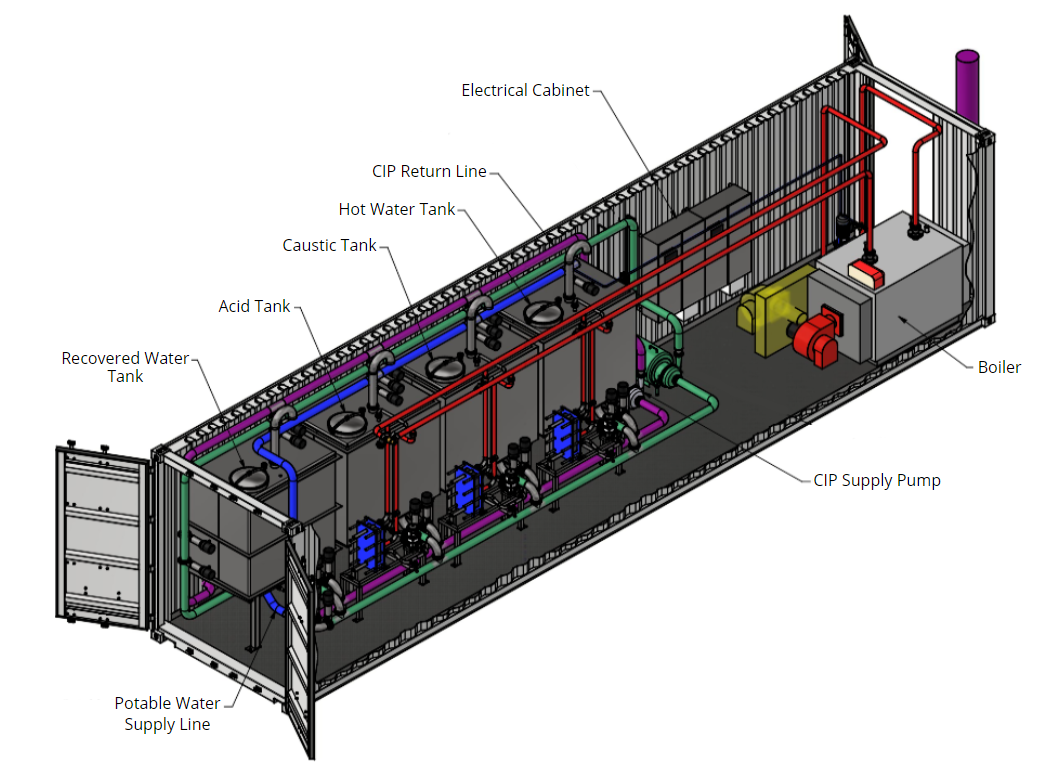

Thermaflo Container CIP Kitchen for Tankers

Tanks required: 4

Tank Size: 2000L

Instrumentation and Control Panel:

-

- Inline and in tank conductivity meters

- Flow meters

- VSD on pumps

- Level transmitter

- Temperature transmitter

- Full PCC and HMI

- 21 step CIP program customised to site requirements

- Automatic Solids Discharge

Construction: 316 stainless steel square insulated tanks. Pipes made with stainless steel 316

Pumps: Stainless steel 316 sanitary design centrifugal pumps

Valves: Fully automated stainless steel 316 sanitary design valves

Boiler Options: Diesel or LPG

- Plug and play with enhanced driver safety – no handling of chemicals, and system will not start without secure hose connections.

- Up to 100,000L/hr flow rate

- Separate Caustic, Acid, Hot water and recovered water tanks

- Fully automated 21 step CIP program including sanitiser dosing

- Data capture system

- Always delivers CIP at the correct temperature, chemical strength and flow rate to ensure optimal tanker hygiene

- Container design enables easy portability.

- Bulk liquid truck and tanker cleaning

- Milk

- Juices

- Wine

- Edible Oils

- Two tanker system (CIP two tankers at once)

- Water and chemical reuse

Manufactured By Thermaflo NZ

We design, fabricate and install supply CIP kitchens designed and built to Australian standards. From a small single use system to a large multi-circuit reuse CIP kitchen we can design a build a system to meet your needs.

Our equipment is designed by our in-house team of process engineers, and fabricated at our workshop by our mechanical and industrial electrical teams.

Thermaflo have done an outstanding job on the project and with the increased capacity of this CIP kitchen, we will be able to start expanding the rest of our process. We always like working with Thermaflo and will happily recommend them to others.”

Corrie den Haring

Green Valley Dairy