Hygienic Filling

Trepko and Filmatic filling options are customiseable, and have a range of hygienic filling options to meet your required shelf life.

Let us know your requirements for; Air management, Cap and containers sterilization and CIP/SIP

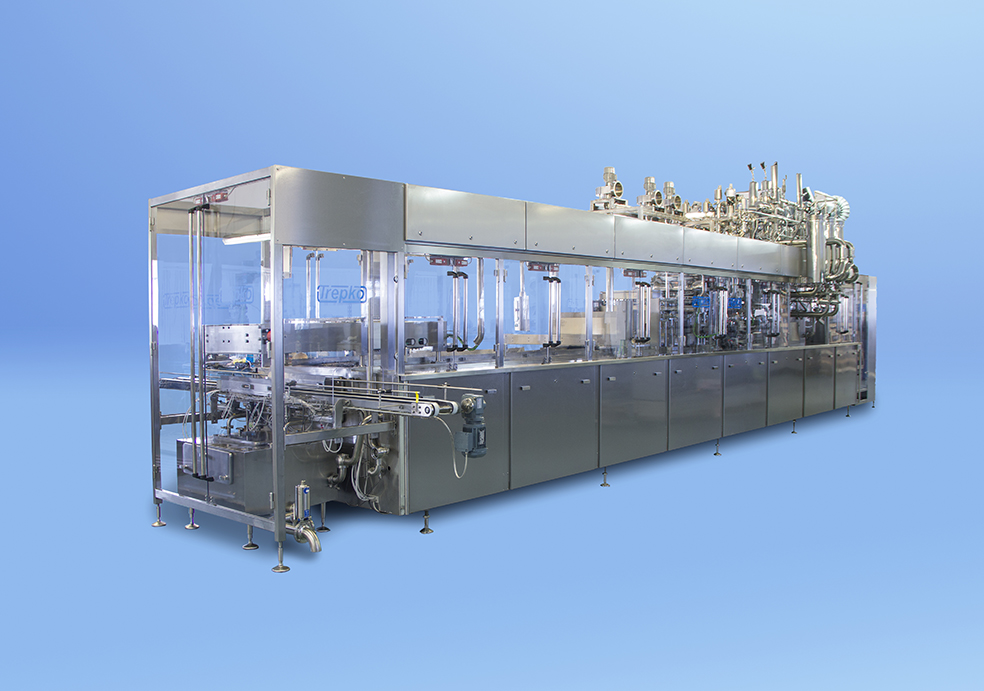

Trepko Inline Aseptic Filling Machine

Number of filler points: Dependent on customer requirements

Number of lanes: Dependent on customer requirements. The standard range comprises of 1, 2, 3, 4, 6, 8 and 10 lanes, single or double index

Maxmum output (cups/h): Dependent on the number of lanes and products being filled

Max. cup dimensions (mm): Up to 200 mm dia

Max. cup height (mm): Up to 130 mm

- The 100 series is suitable for a variety of products including cups and straight-sided containers,

- The modular design allows for bespoke layouts,

- We can configure the machine to meet your exact specifications.

- milk

- cream

- yoghurt

- kefir

- cream cheese

- processed cheese

- mousse

- desserts

- quark

- cottage cheese, (incl with fruit pulp)

- butter/margarine

- jam, honey, conserve

- mayonnaise, dressing, ketchup, sauces

- salads

- pâte

- lard

- pet food

- spreads

- shortening

- Choose from three levels of hygiene: Standard / Ultra Clean / Aseptic

- Closing Options: Foil from reel or vacuum heat-sealing

- Dry fillers

- Pick & place unit

- Pre- and after dosing

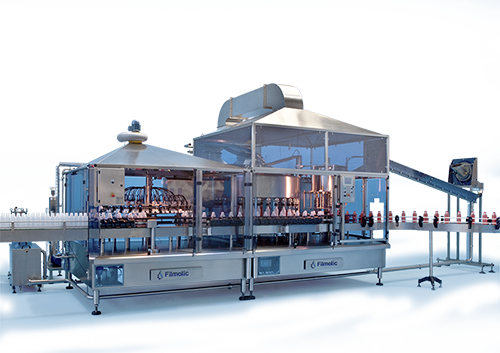

Filmatic ESL Bottle Filling Machine

Bottle Volumes: 250ml – 5000ml

Filling Speed (approx):

1000ml: 7,500 – 9000 Bottles per hour

2000ml: 4,800 – 6,000 Bottles per hour

Machine dimensions (mm): 2,450 (L) x 2,150 (W) x 4,023 (H)

Final filling speed is influenced by product characteristics, container dimensions and valve size.

- The continuous variable flow control valve promotes non-contact, non-drop filling creating a hygienic filling environment while also minimising foaming issues.

- All product contact components are thoroughly cleaned by the closed-loop automated CIP system.

- Accommodate up to three different cap sizes and formats on one machine,with quick change overs between different bottle and cap size.

ESL is a great choice for those with high-value products wanting a longer shelf life, without the additional expense of aseptic technology.

ESL is well suited for products such as

- Milk

- Cream

- Juice etc.

- Available in Level filling and Nett-Weigh options.

Manufactured By Trepko & Filmatic

Trepko is a truly international manufacturer, based in Denmark with sites in Poland, the United Kingdom and Brazil, while Filmatic has its manufacturing base in South Africa.

The brands are so complementary that Filmatic became a subsidiary of the Trepko group in 2015. So although they are two different brands, they are in effect, the same company with shared technology.

Both companies have considerable expertise in filling high-value and delicate products, so they have a strong emphasis on gentle product handling and avoiding waste/spillage.