Homogenisers

FBF Italia manufacturers homogenisers and positive displacement pumps with capacities from 50L/hr through to 50,000L/hr.

Homogenisers are extremely common in dairy processes to disperse the cream in milk or in ice cream mix into a homogeneous emulsion. This prevents the cream from separating over time.

Plant-based diary alternatives (such as oat milk) also require homogenisation to stabilize the product and prevent the plant base and oil particles from separating.

Homogenisers are also used for various different pharmaceutical or laboratory applications. High-pressure pumps are used where very high pressure is required e.g. evaporated milk prior to spray drying or for high viscosity products, such as tomato paste.

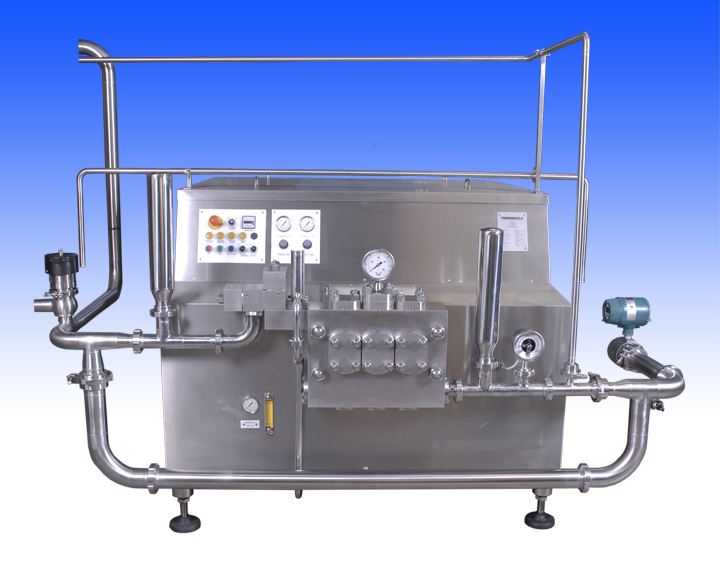

FBF Homogenisers

Flow Rates: 50L Per Hour – 50,000L Per Hour

1st Stage Pressure: 0 – 2000 Bar

2nd Stage Pressure: 0 – 150 bar

- Compression head is manufactured from a single block of high quality stainless steel, checked with ultrasounds, with a 5 year guarantee against cracking and defects.

- Pumping Pistons manufactured with “Diamond-Like Carbon” plating.

- Homogenising valves are efficiently designed with high stability and alignment, ensuring vibration free homogenisation.

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Edible Oils

- Honey

- Soups & Condiments

- Egg Pulp

- Syrups

- Other

- Aseptic option available

- Abrasive version available

- Pulsation dampeners on product inlet and/or outlet connections

- Automatic homogenization pressure controller

- Pressure gauge with alarm contacts for the automatic cut-off of the homogenizing pressure complete with timing device to manage the start/stop of the homogenising valves

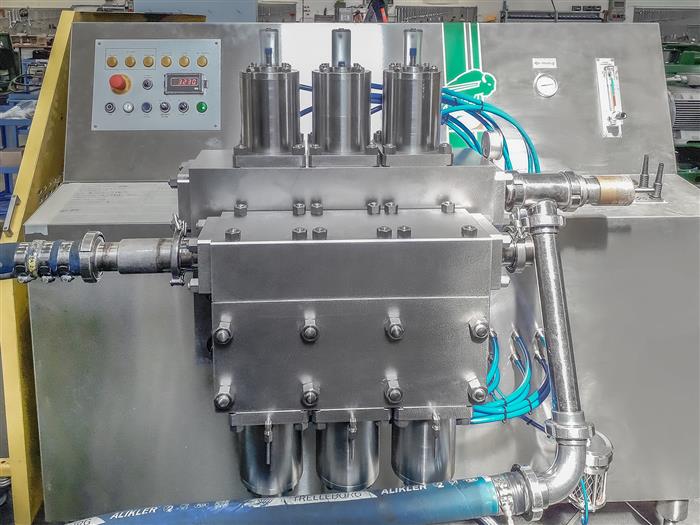

FBF Positive Displacement Pumps

Standard flow rate: from 180 to 3000 gph

Standard pressure range from: 600 to 3000 psi

Standard electric motors from: 3 to 75 kW

- Compression head has a 5 year guarantee against cracks and defects.

- 3A sanitary certification.

- Pistons are made in AISI 316 chromed steel with a “Diamond Like Carbon” coating.

- CIP ready.

- Suitable for treatment of low and high viscosity products.

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Edible Oils

- Honey

- Soups & Condiments

- Egg Pulp

- Syrups

- Other

-

Aseptic Version with “sterility barriers” traced with steam condensate created by a built-in system.

-

Digital pressure transducers and analogue gauges with 4-20 mA output.

-

Pulsation dampeners on product inlet connection.

-

Built-in control system (electrical system, start/stop button, pressure indicators).

-

Inlet pressure gauge with alarm contact.

FBF Lab Scale Homogenisers

Capacity: 20 – 50L/hr

Max Pressure: 1800/150 Bar (2.20 model) or 600/150 bar (2.50 model)

Max particle size: ≤ 0.2 mm / ≤ 0.5 mm

Hopper Capacity: 0.8 – 1.6L

Weight: 110Kg (2.20 model) / 115Kg (2.50 model)

- Homogenising valves made in food-grade tungsten carbide

- Compression head is manufactured from single block high quality stainless steel

- Double homogenizing stage

- 2 pumping pistons

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Edible Oils

- Honey

- Soups & Condiments

- Syrups

- Other

- Hot water jacket for hopper

Manufactured By FBF Italia

FBF have been manufacturing homogenisers since 1987 and have over 5000 installations across food & beverage, chemical, and pharmaceutical sites around the world.

In addition to standard homoginisers they also manufactuer postitve displacement pumps and lab-scale homogenisers.