Separators & Clarifiers

For over 100 years, Frautech have been designing and manufacturing centrifugal disc separators for the food and beverage industry.

They supply plug-and-play solutions that integrate easily into your process, with an extremely efficient separation for your beverage plant or brewery.

Separators / Clarifiers

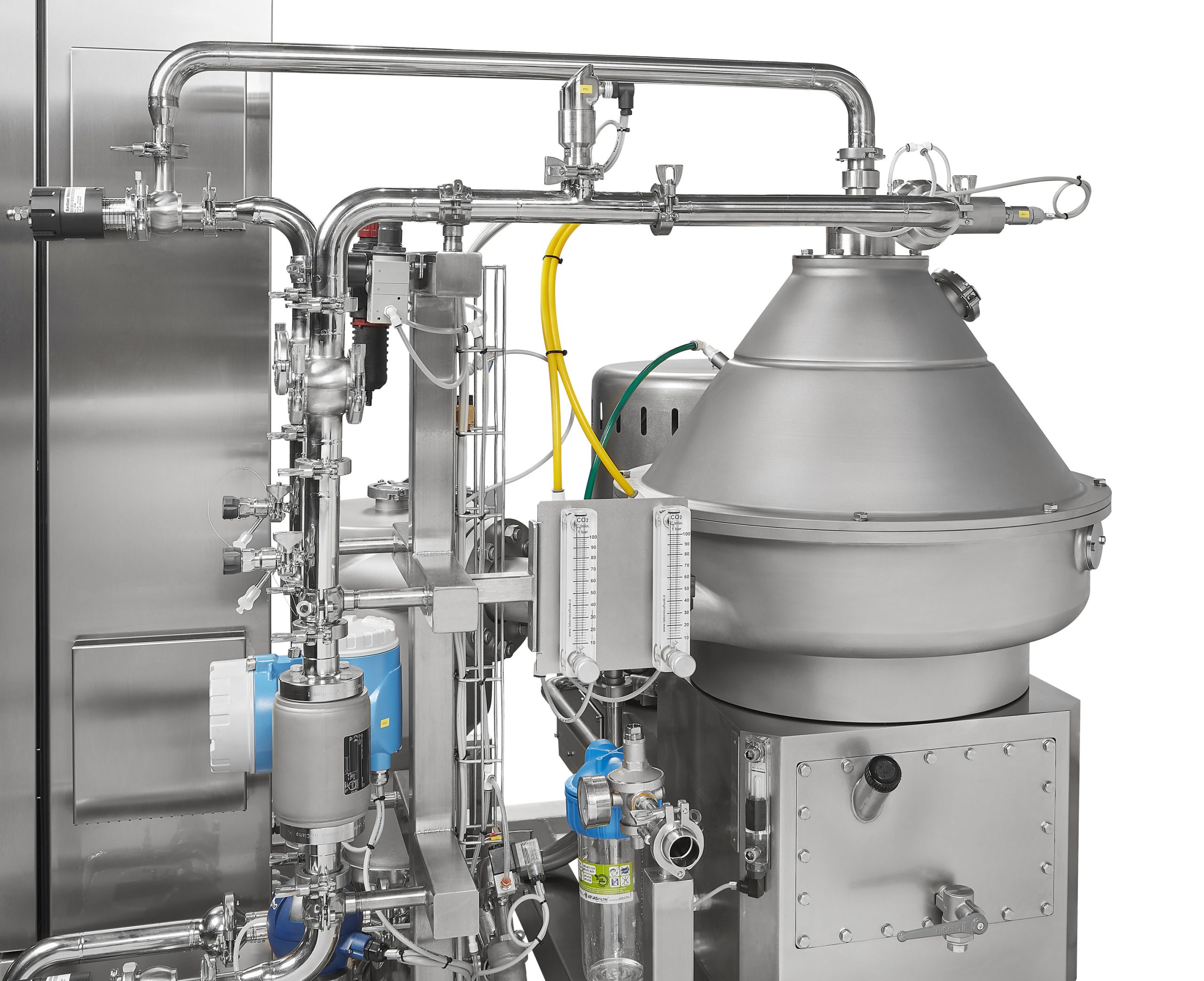

Frautech ArtBREW – Craft Beer Clarifier / Centrifuge

Models available: 5

Beer Clarification Capacity:Up to 50hl/hr to 350hl/hr

Clarification of dry hopping beer: 6 hl/hr – 180hl/hr

- Variable frequency drive

- KO₂ oxygen knock-out device

- On-off feed valve, hood cooling valve, sample port at outlet

- Sight glasses at inlet/outlet

- Flow transmitter with totalizer and manual flow regulating valve

- Manual back-pressure control valve

- Integration into fully automatic CIP(cleaning in place) system

- Low Dissolved oxygen pick-up, typically less than 10 ppb

- Unique inert gas sealing system

- No deaerated water needed and no risk to contaminate the product

- Low operating costs for CO₂ or N

* Capacity depends on the characteristics of the beer

- Beer

- Hot or cold wort clarification

- Trub wort clarification

- Green beer separation

- Cider

- Kombucha

- Local or remote feed pump

- Solids discharge by VolCon system, our perfect control of the discharge volume

- Turbidity monitoring at feed

- Sight glasses with backlighting at inlet/outlet

Frautech ArtBEV – Beverage Clarifier / Centrifuge

Models available: 6

Hydraulic Capacity: 7,500kg to 70,000Kg

- Variable frequency drive

- Tangential cyclone with solids discharge tank

- Liquid ring sealing to prevent oxygen pick-up

- Strainer with manual valves

- Automatic on-off butterfly valve

- Magnetic flow transmitter

- Manual valve for flow-rate control

- Pressure gauge at product outlet

- Manual valve for back pressure control

- Check valve at product outlet

- Sight glasses at product inlet/outlet

- Sampling valves at product inlet/outlet

- Electro-valve for bowl rinsing

- Pressure water reducer and cartridge filter for operating water

- Vibration sensor

ArtBev clarifiers are used for fine clarification after extraction and fining, to remove unwanted solids, haze particles or fining agents before further processing. They are well suited for:

- Juices

- Tea/herbal drinks

- Vegetable drinks

- Wine

- Operating water feeding unit

- Solids discharge by VolCon system, our perfect control of the discharge volume

- Turbidity monitoring and control of TSS level at outlet

- Feed pump

- Solids discharge pump

- Sight glasses with backlighting at inlet/outlet

Manufactured by Frautech Separators

With over 100 years of experience, Frautech separators can be found in dairy, beverage, beer and food plants around the world.