Welcome To Thermaflo

We supply process and filling/packaging capital equipment to the food and beverage industries throughout Australia

If your liquid food or beverage process needs; heating, cooling, mixing, dosing, filling, packaging, or cleaning, our team is here to help.

Food & Beverage Capital Equipment At A Glance

Process Equipment

Blend, Mix & Dosing

Options:

Applications:

- Mixing fruit pieces or puree into a viscous-base

- Ice cream mixing

- Beverage blending

- Yoghurt ingredient mixing and dosing

- Oil dosing

- Ingredient hydration

Homogenisers

Options:

Applications:

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Edible Oils

- Honey

- Soups & Condiments

- Syrups

- Other

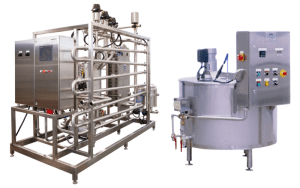

Pasteurisers

Options:

Applications:

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Edible Oils

- Honey

- Soups & Condiments

- Egg Pulp

- Syrups

- Other

Cheese Process Lines

Ice Cream

Plant Based Dairy Alts

Applications:

- Milk alternatives

- Butter alternatives

- Yoghurt and other fermented products

- Ice cream alternatives

- Cheese alternatives

- Plant-based Condiments/Sauces

CIP Systems

Options:

Applications:

- Food and Beverage plant cleaning

Bulk liquid truck and tanker cleaning

Lab Scale

Options:

- Direct Steam Injection UHT/HTST

- Tube & Plate UHT/HTST

- Scraped Surface Heat Exchanger

- Lab Scale Retort

- Lab Scale Homogenisers

- Lab Scale Mixers

- Margarine & Spreads Processor

- Lab Scale Membrane System

- Pilot-Scale Cheese Plants

- Custom Solutions

Applications:

Lab scale processing for:

- All Dairy products

- Plant-based milk alternatives (Coconut, Almond, Oat, Soy etc)

- Juice (vegetable & fruit)

- Soups & Condiments

- Spreads

- Desserts

- Mixed fat products

- Margarine

- Fractionation, purification and concentration of molecules

- Colostrum processing

- Nutraceutical and collagen extraction

Separators / Clarifiers

Options:

Applications:

- Beer

- Cider

- Kombucha

- Juice

- Plant-Based Dairy Alternatives

- Wine

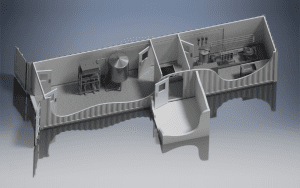

Containerised Process

Options:

Applications:

Small scale production of

- Milk

- Cheese

- Juice

- Yoghurts

- Plant-based dairy alternatives

- Other beverages or liquid food

- Liquid cosmetics (eg. skin cream)

- Nutraceutical products

Membrane Filtration

Options:

Applications:

- Sterilisation

- Concentration

- Purification

- Clarification

- Part Demineralization and Concentration

- Concentration and Enrichment

Yoghurt

Options:

Applications:

- Pot set yoghurt

- Stirred yoghurt

- Drinking yoghurt

- Greek yoghurt etc

- Dairy & Plant based yoghurts

Decanters

Options:

Applications:

- Beverage extraction (wine, juices)

- Beverage solid reduction (wine, juices, plant-based milk)

- Dairy (casein, lactose, calcium phosphate)

- Oil and fats (olive oil — two and three phases, animal blood, animal fat)

- Green chemicals (starch, proteins, bioethanol, vinasses K2SO4)

Mixing & Cooking

Options:

Applications:

- Sauces/condiments/pastes/dressings

- Chocolate

- Icing

- Fruit desserts

- Jam/marmalade

- Chutney

- Ready meals

- Pie filling

- Soups

- Babyfood

- Analogue Cheese

- Plant-based cheese

Filling & Packaging Machines

Bottle Filling

Options:

- Semi-Automatic Bottle Fillers

- Fully Automatic Rotary Level Fillers

- Fully Automatic Rotary Piston Fillers

- Fully Automatic Rotary Nett-Weigh Fillers

- Fully Automatic Linear Pump Fillers

- Fully Automatic ESL Fillers

Applications:

- Milk

- Cream

- Drinking Yoghurt

- Plant-based Milks

- Juice

- Edible oils

- Sauces/condiments

Butter Wrapping & Filling

Options:

Applications:

- Butter

- Butter with vegetable oils

- Margarine

- Lard

- Cream cheese

- Minced meat

- Fromage frais/Quark/Tvorog etc.

- And similar products

Can Filling

Options:

Applications:

- Carbonated beverages

- Soft Drinks

- Beer

- Sparkling Wine

- Cider

- Kombucha

- Sparkling water / juice

- Still beverages

- Juices

- Water

- Still wine

- Other beverages

Carbonated Bottle Filling

Options:

Applications:

Carbonated beverages into bottles:

- Beer

- Wine

- Cider

- Soft drinks

- Kombucha

- Sparkling water

- Sparkling juices

- Etc.

End of Line

Options:

- Box Cartoning Machines

- Palletisers

- Pick & Place Systems

- Shrink Wrapping Machine

- Tray Erectors

- Wrap Around Packer

- Wrap Around Sleever

Applications:

- Handling tubs, cups & pottles

- Packing into cases, trays, cartons

Form, Fill, Seal

Options:

Applications:

- Yoghurt

- Plant based dairy alternatives

- Cream

- Cream cheese

- Processed cheese

- Jam/marmalade

- Hone

- Sauces

- Mousse

- Puree

- Mini-sized portions of the above (10,15,25g)

Hybrid Bottle/Can Filling

Options:

Applications:

- Fill glass bottles and aluminium cans on the same machine

- Carbonnated beverages

- Soft Drinks

- Beer

- Sparkling Wine

- Cider

- Kombucha

- Sparkling water / juice

Hygienic Filling

Options:

Applications:

Hygienic filling of:

- Milk

- Cream

- Yoghurt

- Cream cheese / processed cheese

- Mousse / Desserts

- Butter/margarine

- Jam, honey, conserve

- Mayonnaise, dressing, ketchup, sauces

- Salads

- Pet food

- Spreads

Tub & Cup Filling

Options:

- Index Tub Fillers

- Rotary Tub Fillers

- Carousel Tub/Cup Fillers

- Inline Aseptic Tub Fillers

- Semi-automatic Tub Fillers

Applications:

Filling viscous product into tubs/cups

- Butter/margarine

- Cream cheese

- Cream

- Yoghurt

- Desserts

- Processed cheese

- Spreads

- Jam/marmalade/honey etc

- Sauces/puree/mayonnaise

- Other viscous products

Industries We Operate In

Milk

Juice

Plant-Based

Sauces

CIP Kitchens

Beer

Honey

Cheese

Yoghurt

Ice Cream

Petfood

Nutraceuticals

Dips & Spreads

In-House Expertise

Through our New Zealand head office and fabrication workshop, we also have in-house teams of process engineers, stainless steel fabricators, industrial electricians and automation engineers.

Our team of process engineers will help you design or upgrade your process to meet your requirements.

Our in-house mechanical and electrical teams, will then build, deliver, and commission this for you.

Some Of Our Previous Work

Thermaflo have worked for TruBlu since 2013, during this time they have designed, fabricated, supplied and commissioned several projects.

These include 3x HTST pasteurisers for our QLD, NSW and WA plants, secondary modifications to our WA pasteuriser and a CIP Kitchen for our NSW plant.

What impresses us here at TruBlu is that Thermaflo are able to understand our requirements and translate these into integrated process plant solutions that are highly functional and competitively priced.

We enjoy working with the staff at Thermaflo as they are responsive, knowledgeable and committed to providing the best outcomes for us.

Most of the projects we have engaged Thermaflo to supply have been within tight timeframes and they have always delivered on time and to budget.

All of the above projects have gone very well with successful delivery and commissioning of the plants.

David Pryor

Executive Director, Tru Blu Beverages

We first started dealing with Thermaflo in 2003 when we purchased a 1,500 ltr per hour HTST pasteuriser plus installation and commissioning to meet our growing demand for our cheese products.

This went very well and the pasteuriser was delivered, installed and commissioned to our satisfaction. Over the preceding years we have got to know the Thermaflo staff well and they have been our trusted partners with the designed, built, supplied / installed and commissioned several upgrades to our plant to meet increasing sales.

These upgrades included a new HTST pasteuriser at 3000L/hr and a yoghurt manufacturing and filling process.

More recently a pipe work / automatic valve upgrade to integrate a new cheese vat system for making halloumi / feta / ricotta cheese.

The various installations included the complete electrical supply / wiring as well as the automation, Thermaflo’s in house electrical team have always performed well and are professional tradesmen.

We see Thermaflo as being part of our team in that they not only design and supply top quality plant and have the know how to integrate this into a functional process, but they also have great ongoing support when we need it.

I am very happy to recommend Thermaflo to others as I know they will do a great job.

Michael Gavriel

Owner, Olympus Cheese

Our New Zealand based fabrication workshop and design office supplies:

- Pasteurisers (batch & inline)

- Tanks & Vessels (including specialty tanks)

- Ingredient blending/mxing & dosing equipment

- Cheese vats

- Yoghurt plants

- Ice Cream mix plants

- CIP Kitchens

- Pilot plants

- Containerised process plants

- Process engineering design services

- Electrical / Automation services

- Stainless steel fabrication

See more at www.thermaflo.co.nz

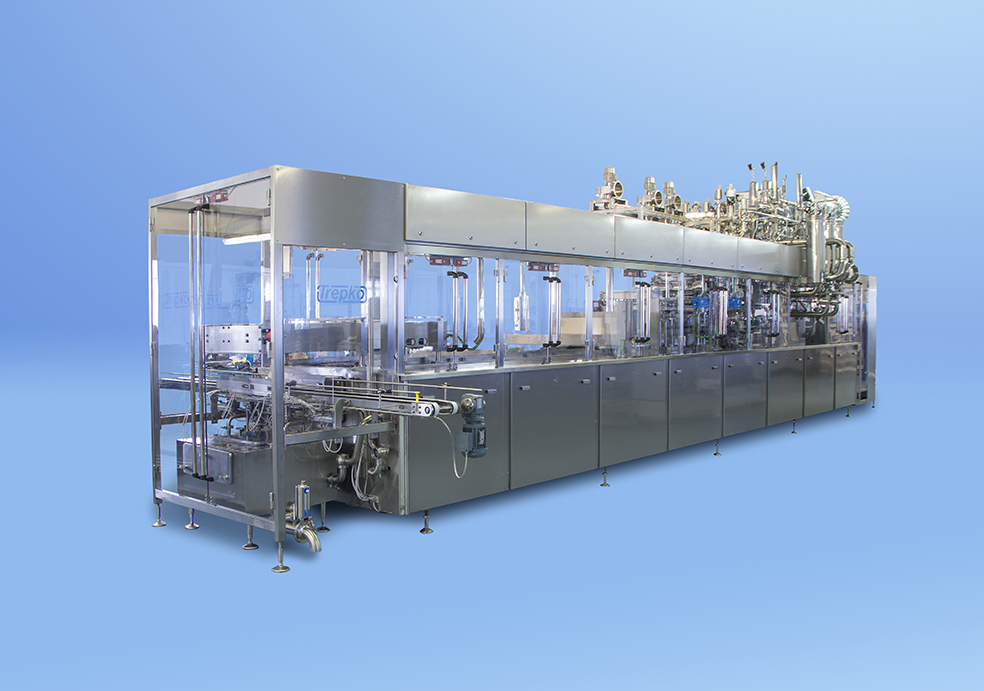

Trepko is a global supplier of filling/packaging machines for the food & beverage industries.

Head Office: Denmark

Thermaflo is the exclusive Australasian sales and integration partner for Trepko.

Trepko supply:

- High-speed inline tub/cup fillers

- High-speed rotary tub/cup fillers

- Bag in box lines

- Brick forming and wrapping

- Bulk filling, forming and wrapping

- Semi-automatic butter bulk packaging

- Form, fill, seal machines (incl mini-portions)

- End of line solutions

See more at www.trepko.com

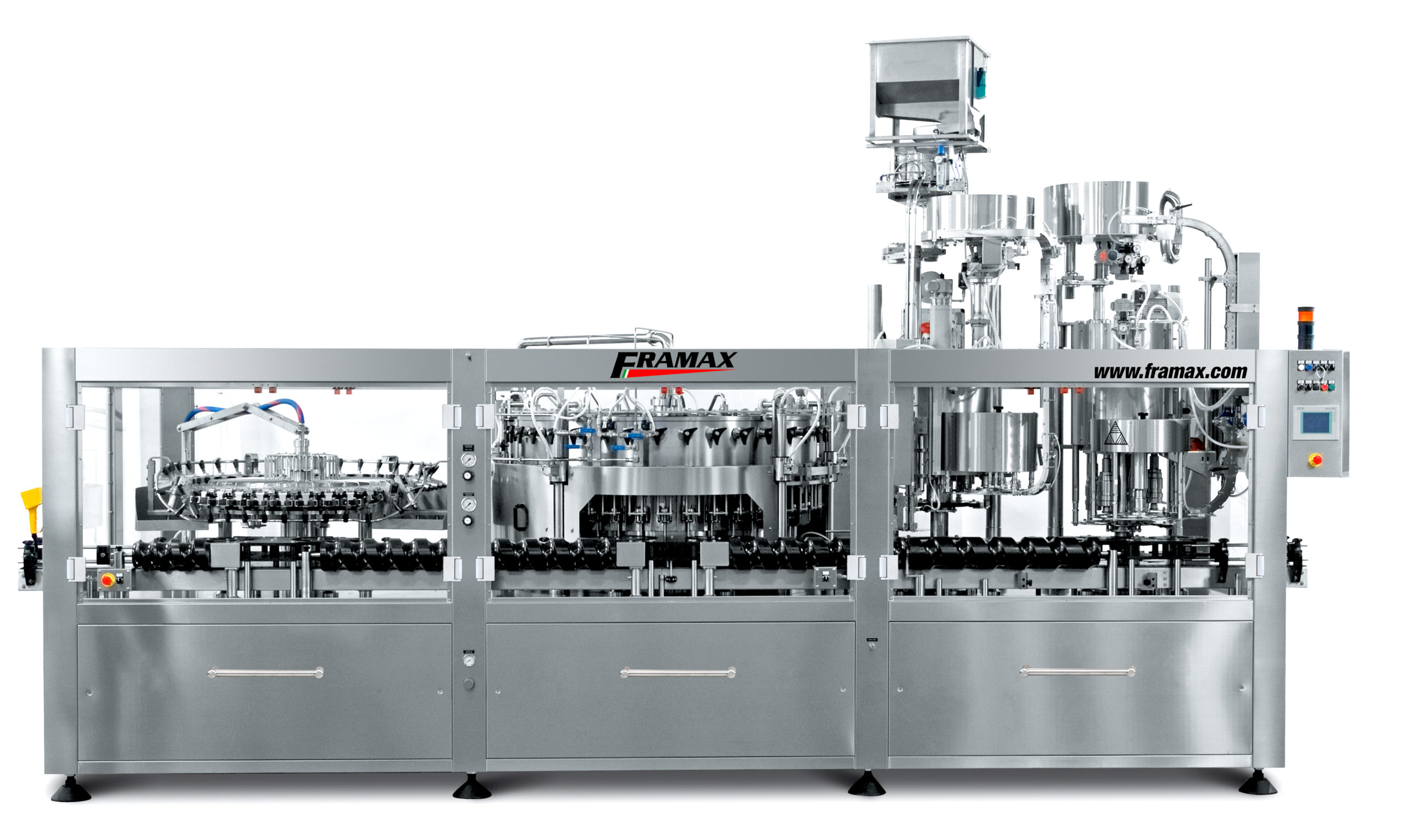

Filmatic is a subsidiary of Trepko, and is a global supplier of filling/packaging machines for the food & beverage industries.

Head Office: South Africa

Thermaflo is the exclusive Australasian sales and integration partner for Filmatic.

Filmatic supply:

- Semi-automatic bottle filling machines

- Level filling machines

- Piston filling machines

- Nett-weigh filling machines

- Index tub filling machines

- Linear pump filling machines

See more at www.filmatic.com

Head Office: Japan

Thermaflo is the exclusive Australia & New Zealand sales and integration partner for Powerpoint International.

Powerpoint International supply:

- Mobile Mini UHT

- Mini Plate UHT/HTST

- Tube in Tube UHT/HTST

- Tube and Plate UHT/HTST

- Direct Steam Injection UHT/HTST

- Scraped Surface Heat Exchangers

- Margarine and Spreads Processors

- Class 100 Clean Bench

- Lab-scale Homogenisers

See more at www.pp2k.com